Belt Conveyor Configurations & Varieties

페이지 정보

작성자 Katrice Partlow 작성일 24-03-22 02:48 조회 7 댓글 0본문

These are simply some of the commonest belt conveyor types. Depending on your application’s particulars and unique specifications, a distinct or custom-made solution may be required. To study extra about what belt conveyor kind is right for you, contact mk North America today. A number one designer and producer of conveyor techniques, mk offers custom and commonplace conveyor systems for industries like manufacturing, machine building, metal working, packaging, printing, and many more. The conveyor belt system’s extremity unit usually contains any pulleys and clamping straps. Additional stands or lateral guides may very well be necessary for specific variations or functions, so consider your industry’s needs when selecting these optional add-ons. The body: The system’s framework holds the entire moving components together for safe and safe operation.

The belt is one in all a very powerful elements of any sort of conveyor system, механическая стыковка транспортерной ленты so it have to be working accurately. Conveyor systems are used for simpler transportation, distribution, and materials dealing with, and there is a variety of economic and industrial conveyor belts in the marketplace. For many who use a conveyor system, it may be difficult to differentiate between all of the conveyor belt sorts. The pulley that powers a conveyor belt is referred to because the drive pulley and has an unpowered idler pulley. Pulley drives at the discharge finish of a conveyor belt are known as head drives, while ones located on the infeed finish are often known as tail drives. The preferred sort of pulley drive is a head drive located on the discharge finish and uses pull power to move a conveyor belt.

But the implications can be less excessive than this. Mistracking may merely result in uneven belt wear, which is the reason for an entire host of different issues in its own right. If the belt slips fully off the observe, the entire system may start malfunctioning and shut down. They work extra just like the chain on a bike. They have an enormous benefit over flexible belts because of this. It makes them strong because they will work in a variety of temperatures and PH levels. When a bit of the belt will get broken, it is easy to simply exchange that section. The carcass can also include the edge protection that is essential in bulk conveyor belts. This is a versatile materials made from rubber or PVC. The covers are uncovered on to the weather and the working atmosphere. Depending on how the covers shall be used, they must be carefully chosen.

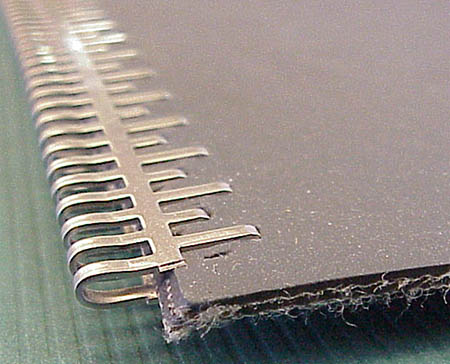

Lifting - A belt lifter safely lifts and holds a tensioned conveyor belt to arrange it for secure repair. Clamping - Engineered belt clamps are particularly designed to correctly safe a belt and clamp it for safe belt conveyor maintenance. Chopping - Belt cutters minimize the danger of accidental damage through the belt slicing course of, providing a safer, faster, and more correct possibility for chopping a belt than a utility knife. Skiving - Belt skivers take away the top cowl of conveyor belts for installation of recessed splices in a safer method than using knives by utilizing and enclosed blade. Whenever you compare the cost of utilizing Flexco belt upkeep tools with the time and money lost to belt repair and maintenance accidents, the choice is clear. High-high quality Flexco tools present a safer different to belt conveyor maintenance on your operation and your workers.

Some cleats with this form also have curved faces, which permits them to scoop granules. This kind of cleat is designed to hold gentle- to medium-weight bulk materials up steeper inclines. • Inverted "V." Cleats with this shape are normally 2 inches or much less in peak to allow for a troughing effect. They’re best for transporting abrasive, heavy, or giant-piece bulk supplies, as they will withstand heavy impacts. The push and press-to-launch mechanisms are simple and applicable for connectors of different cross-sections and shapes. They allow for simple connection and disconnection of cables. To connect wires or cables, merely push them till they click on into place. A launch mechanism is used to release the locking mechanisms and allow the cables to be eliminated. Push and launch connectors are made for use with a specific gauge or wire dimension.

- 이전글 Definition And Authorized Examples Of Gambling

- 다음글 жұбайлардың бірлескен кәсіпкерлігі пепперони халяль купить, колбасные изделия казахстан

댓글목록 0

등록된 댓글이 없습니다.